Our projects

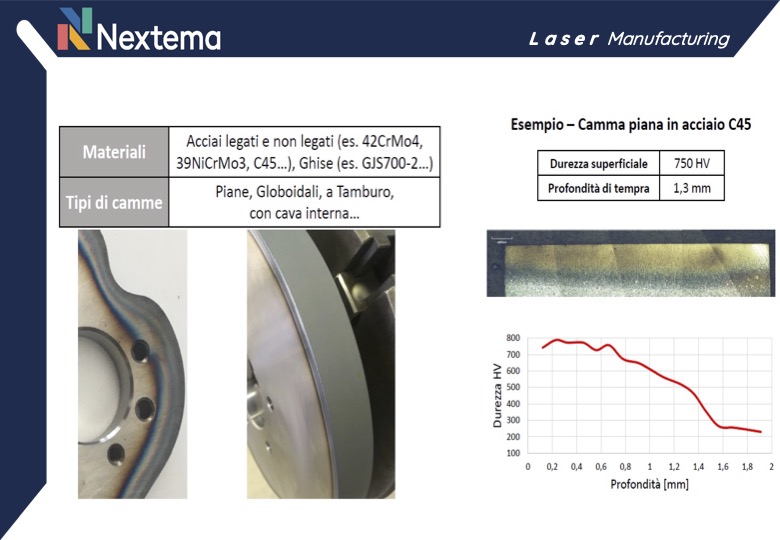

Nextema, making use of his laser hardening plant, offers the possibility to accomplish a variety of hardening works on a large spectrum of mechanical components. The versatilty of the hardening technology, while keeping high quality standards, is one of the top priorities for our business.

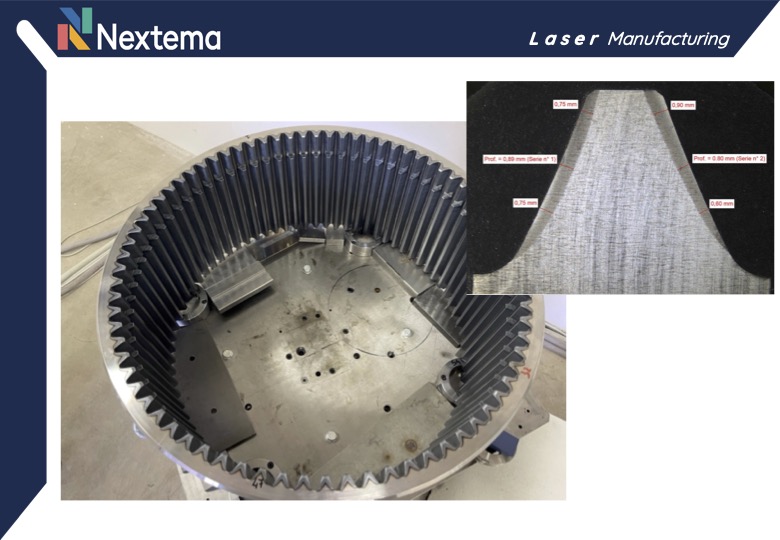

The hardening of the cogs is done by processing one side at a time, with the possibility to modulate the treatment on the head or on the base. Moreover, it is also possible to process external and internal spikes with high depths.

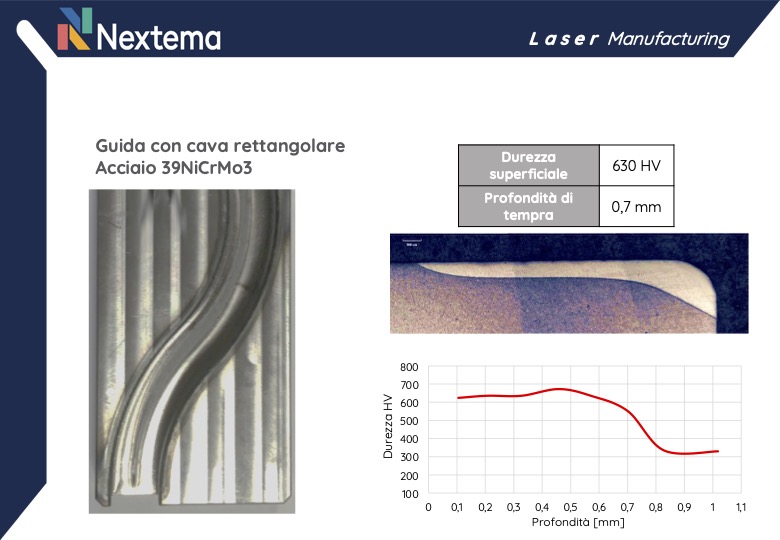

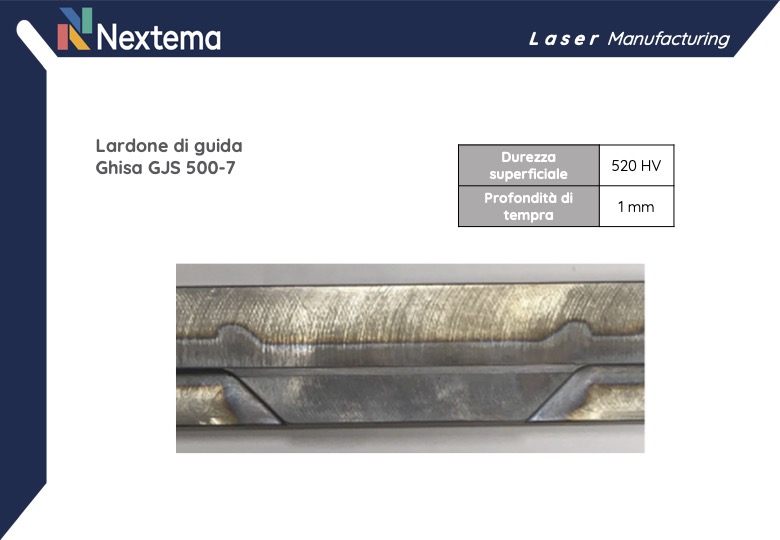

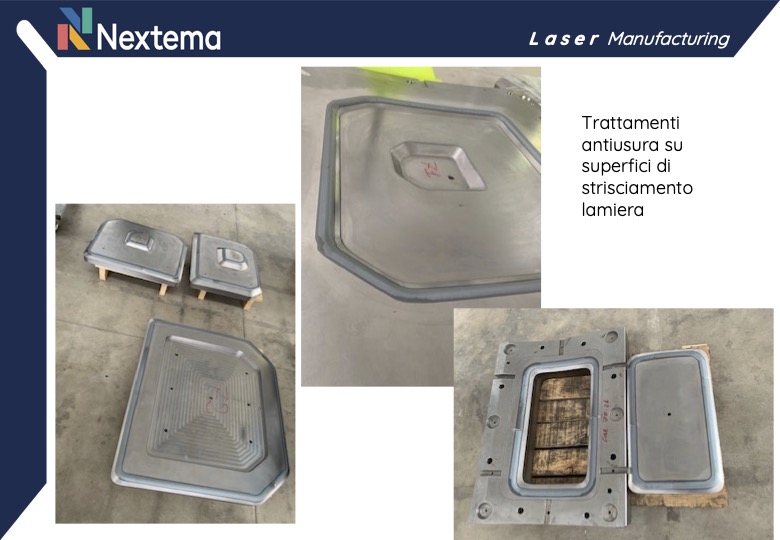

For its reliability and precision, the laser hardening process is ideal for both rolling or sliding guidance components. For depths up to 1mm, remanufacture is usually not necessary.

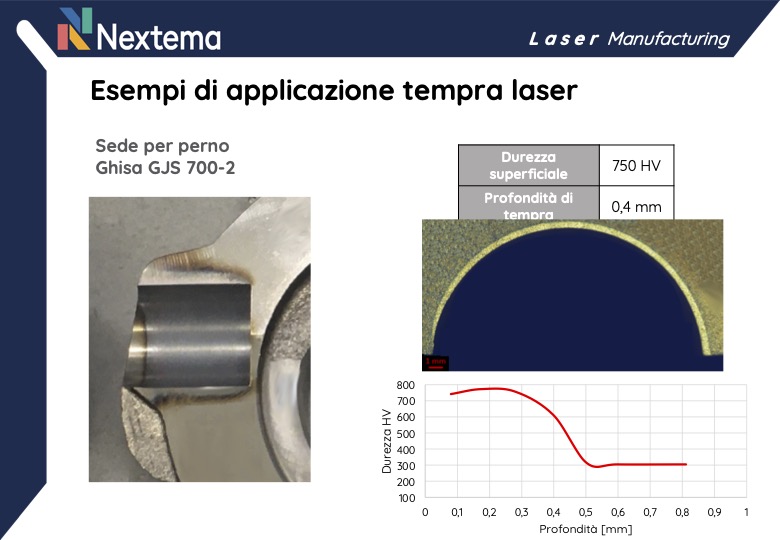

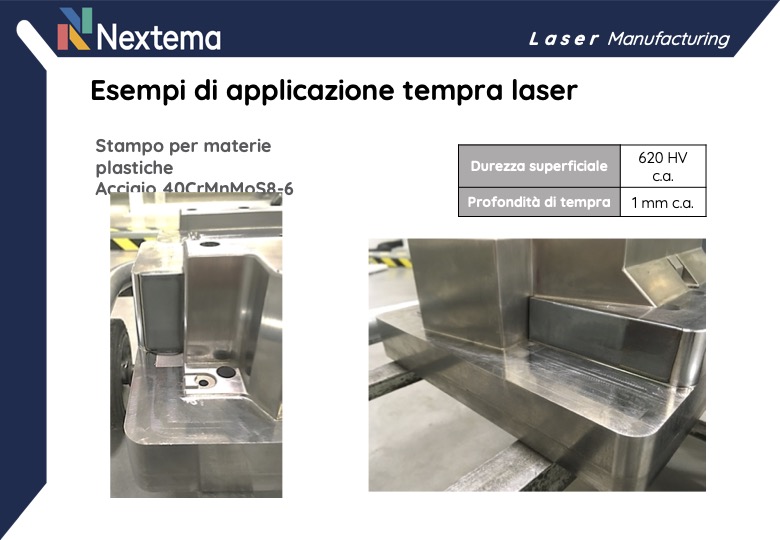

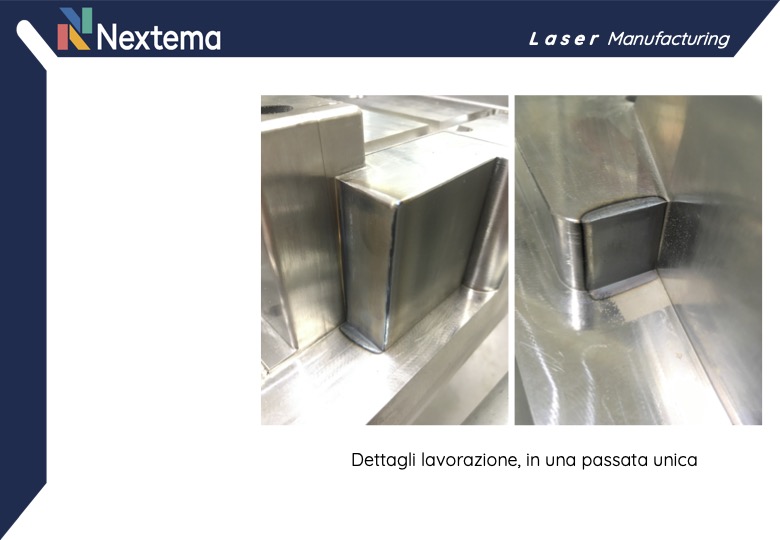

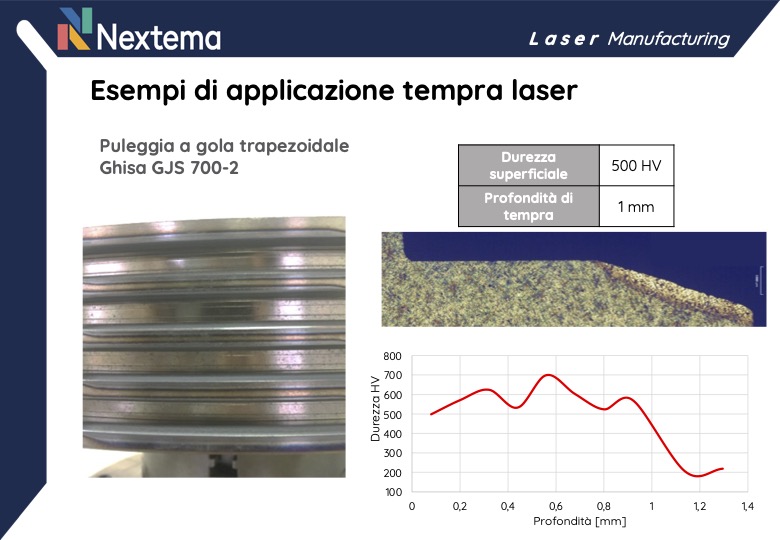

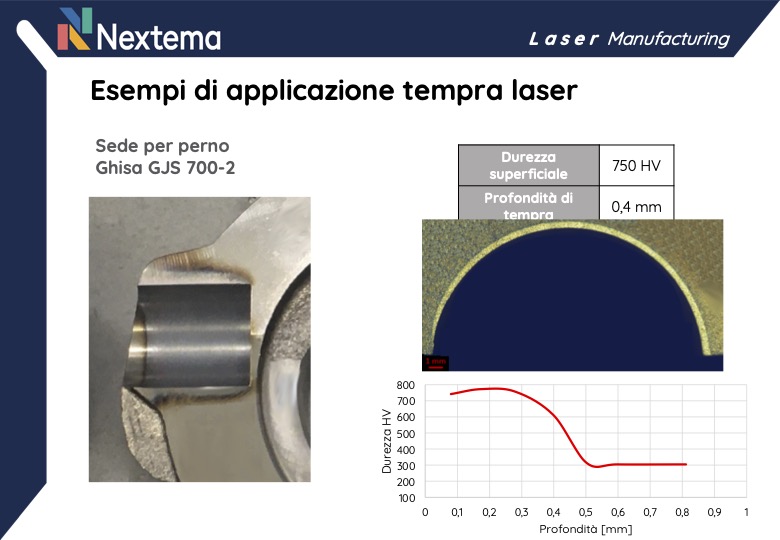

The laser hardening treatment allows to selectively harden wearing surfaces, without any kind of geometric distortion. It is also possible to process unremediated steels and cast irons , both in the construction and maintenance process.

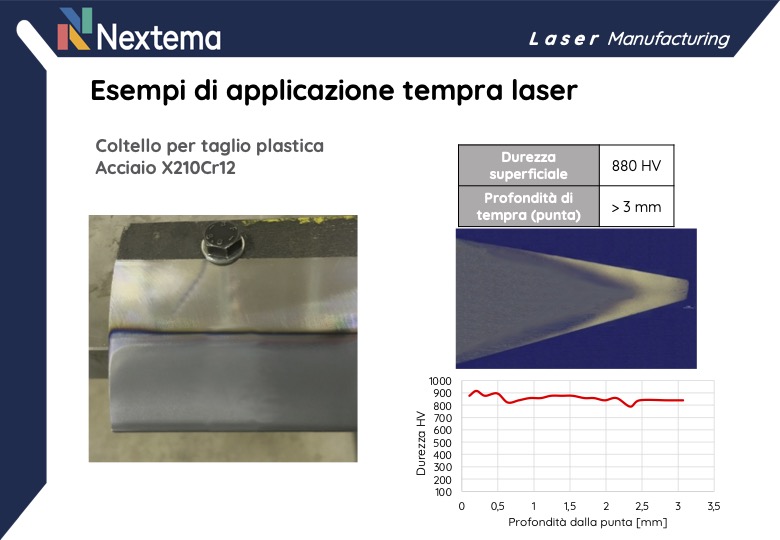

For wearing-prone components, laser hardening allows to maximize the hardness of the material without any kind of microstructural damage.

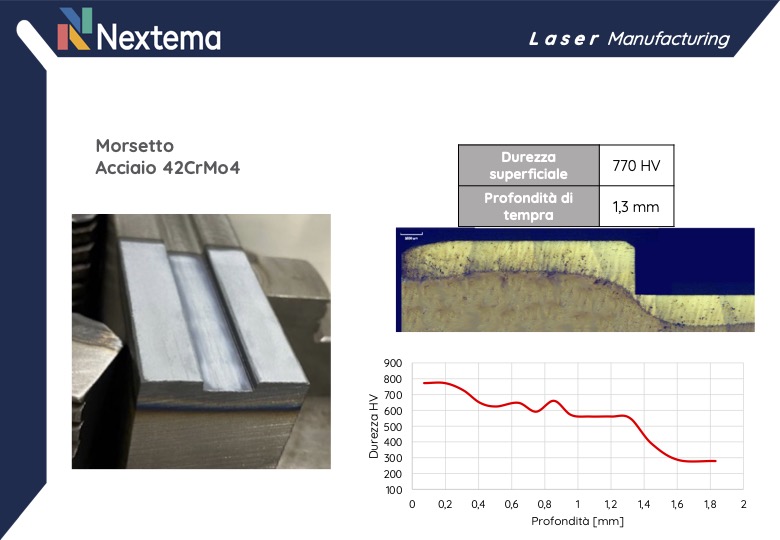

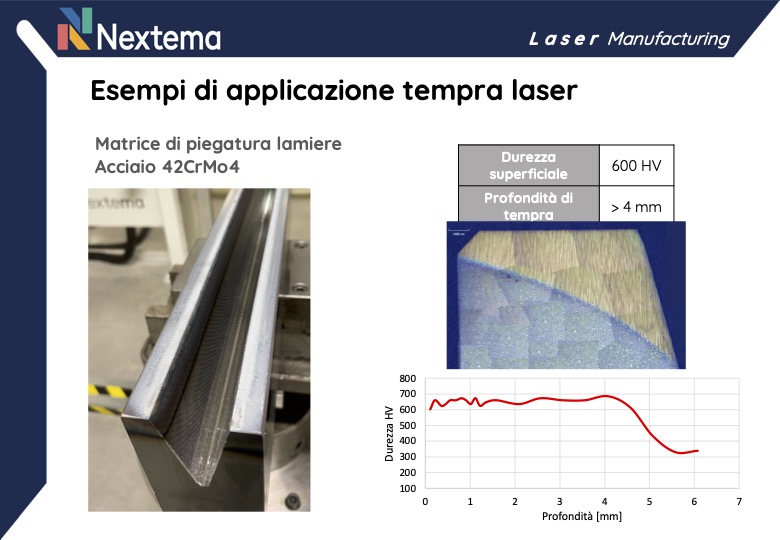

The laser hardening allows to harden striking surfaces keeping a high dimensional precision of the component. In this way the recovery processing is reduced or non-existent at all.